With the rapid development of Industry 4.0, the manufacturing industry is moving towards a smarter, more automated production model. Through the Internet of Things (IoT), Artificial Intelligence (AI), Cloud Computing, and Edge Computing, companies can monitor equipment status, optimize production processes, and even perform predictive maintenance in real time. However, to truly implement these technologies, organizations need a high-performance, rugged, and scalable industrial computer to serve as the core control unit for smart manufacturing.

ICOP's PPC-104T-EHL industrial touch PC is designed to meet this transformational need. Equipped with Intel® Elkhart Lake processors, fanless design, rich I/O interfaces and wide temperature operation, the PPC-104T-EHL is capable of handling applications such as smart factories, automated production lines, machine vision, and warehouse management, helping enterprises to maintain their competitive edge in the era of Industry 4.0.

The evolution of smart manufacturing has made automation a key factor in maintaining enterprise competitiveness. The widespread adoption of robotic arms, automated warehousing systems, and AGVs (Automated Guided Vehicles) has solidified industrial computers as essential control units. Various industries require industrial touch panel computers to control robots, automated production lines, and machine vision inspection systems. However, traditional Industrial PCs (IPCs) often lack expansion capabilities, making them incompatible with new technologies.

The PPC-104T-EHL is equipped with an Intel® Elkhart Lake (EHL) processor, offering higher computing performance and lower power consumption compared to previous-generation platforms. It supports up to 32GB LPDDR4 RAM and provides SATA and eMMC storage options, allowing flexible expansion based on application requirements. This model is specifically designed for industrial automation, Human-Machine Interface (HMI), smart warehousing, and logistics applications, ensuring real-time data processing and high-performance operation.

The PPC-104T-EHL features a 10.4-inch full-flat industrial-grade touch panel display with a resolution of 800 x 600 and 500nits LED brightness. It is designed to withstand dust, oil, and high humidity levels found in industrial environments, enhancing product durability. Additionally, the device offers a resistive touch panel, while its front panel meets IP65 dustproof and waterproof standards, ensuring smooth and stable operation across various industrial applications.

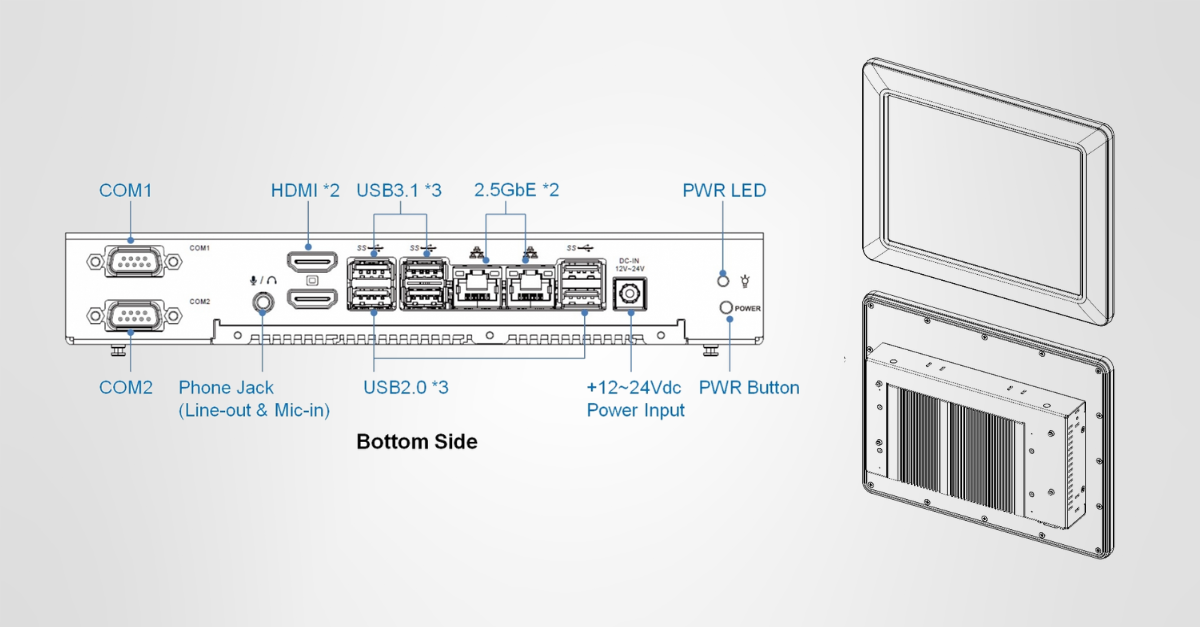

The PPC-104T-EHL is equipped with a comprehensive set of I/O interfaces, including RS-232/422/485, USB 3.1, dual Intel® i225-V 2.5GbE LAN, and HDMI, allowing seamless connection with various industrial devices. Furthermore, it supports M.2 (PCIe 3.0 x2/SATA) NVMe SSDs, enhancing Industrial IoT (IIoT) flexibility. The chassis is built with a fanless aluminum alloy enclosure, offering a wide operating temperature range from 0°C to 60°C, making it ideal for harsh industrial environments and ensuring long-term stable operation.

In the Industry 4.0 era, businesses that continue to rely on outdated industrial computers may face challenges such as reduced production efficiency and increased maintenance costs. Upgrading to a new-generation industrial computer like the PPC-104T-EHL not only enhances system performance and expansion capabilities but also helps companies maintain their competitive edge in an increasingly demanding market.

To help you better understand the specifications and applications of the PPC-104T-EHL, we offer a complete set of technical documents for you to download:

For more info and sample request, please write to info@icop.com.tw, call your nearest ICOP Branch, or contact our Worldwide Official Distributor.