As 6-axis robot arm adoption grows, system integrators and OEMs often face complex control, tight synchronization requirements, and HMI–motion integration challenges.

A Practical EtherCAT Architecture and Development Workflow

Enabling System Integrators and OEMs to Accelerate Robot Arm Application Development

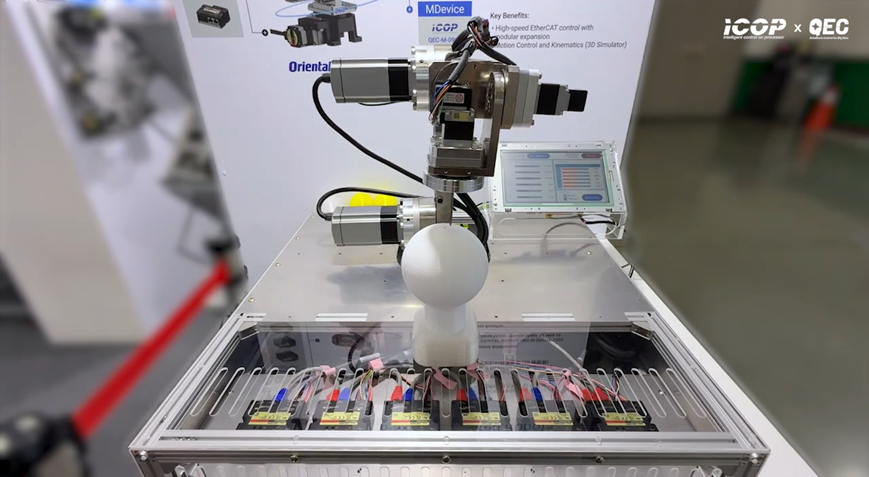

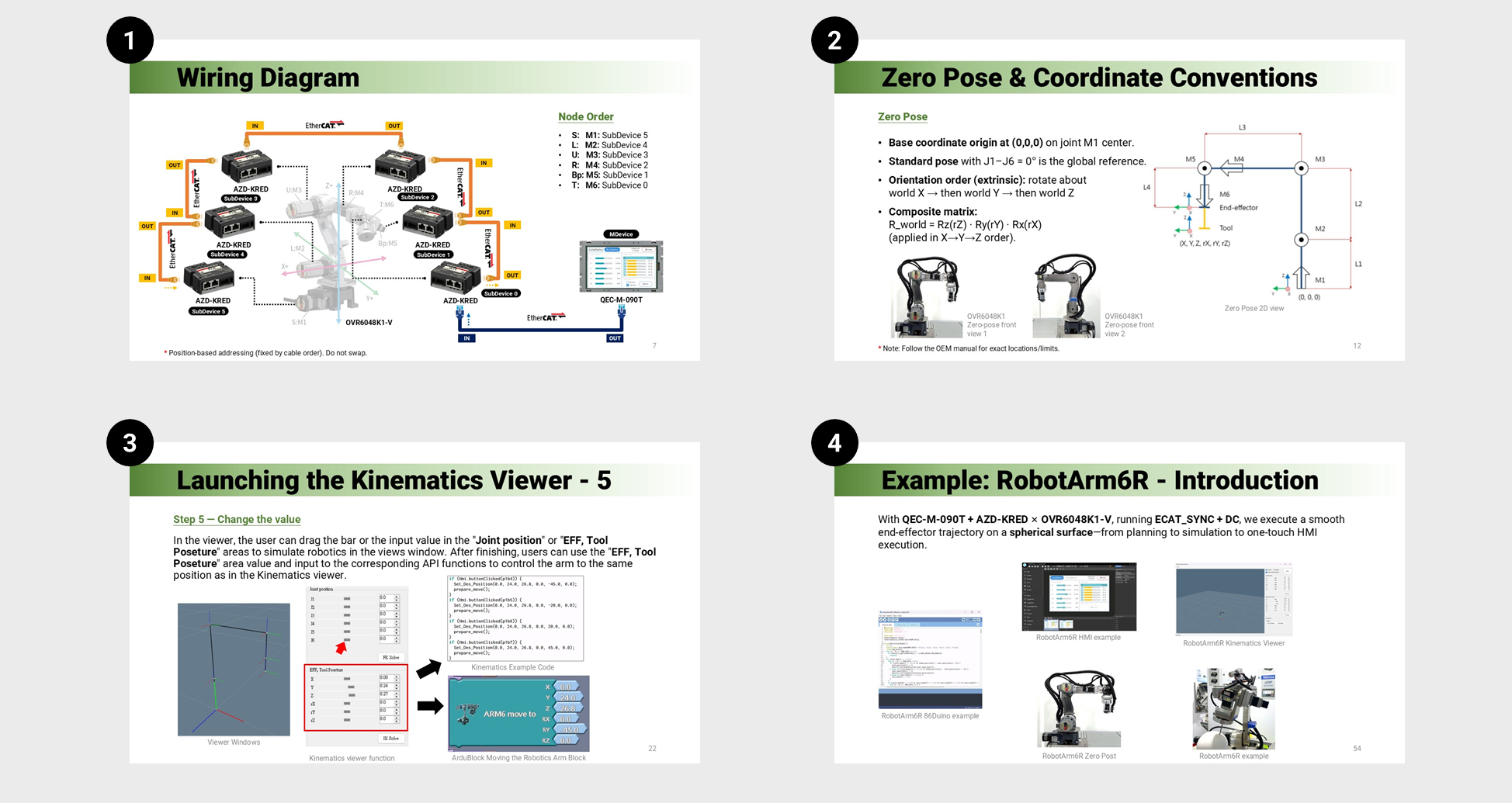

ICOP Technology has recently completed an integration and control validation of the Oriental Motor OVR series 6-axis robot arm using the QEC EtherCAT MDevice platform. This validation demonstrates an EtherCAT-based robot arm control and development architecture that is suitable for real machine deployment, serving as a technical reference for system integrators and OEMs performing secondary development and project integration.

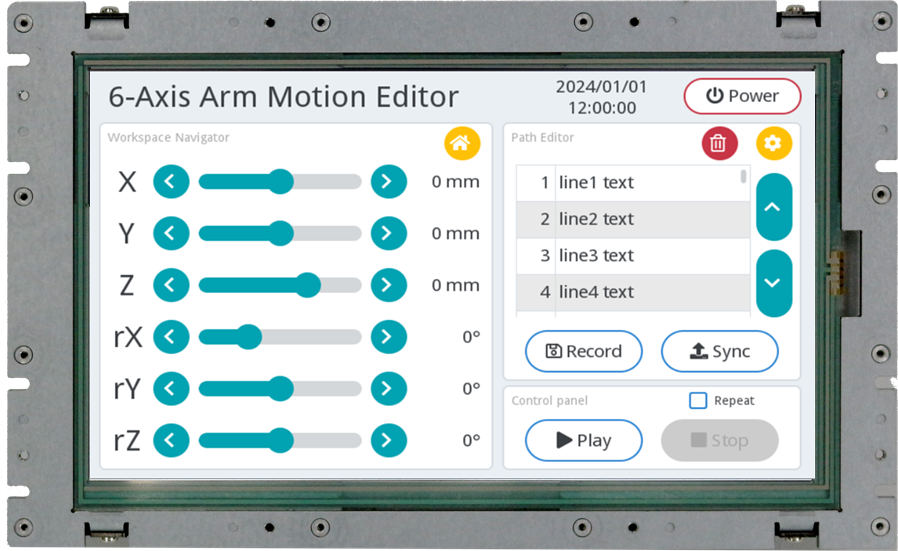

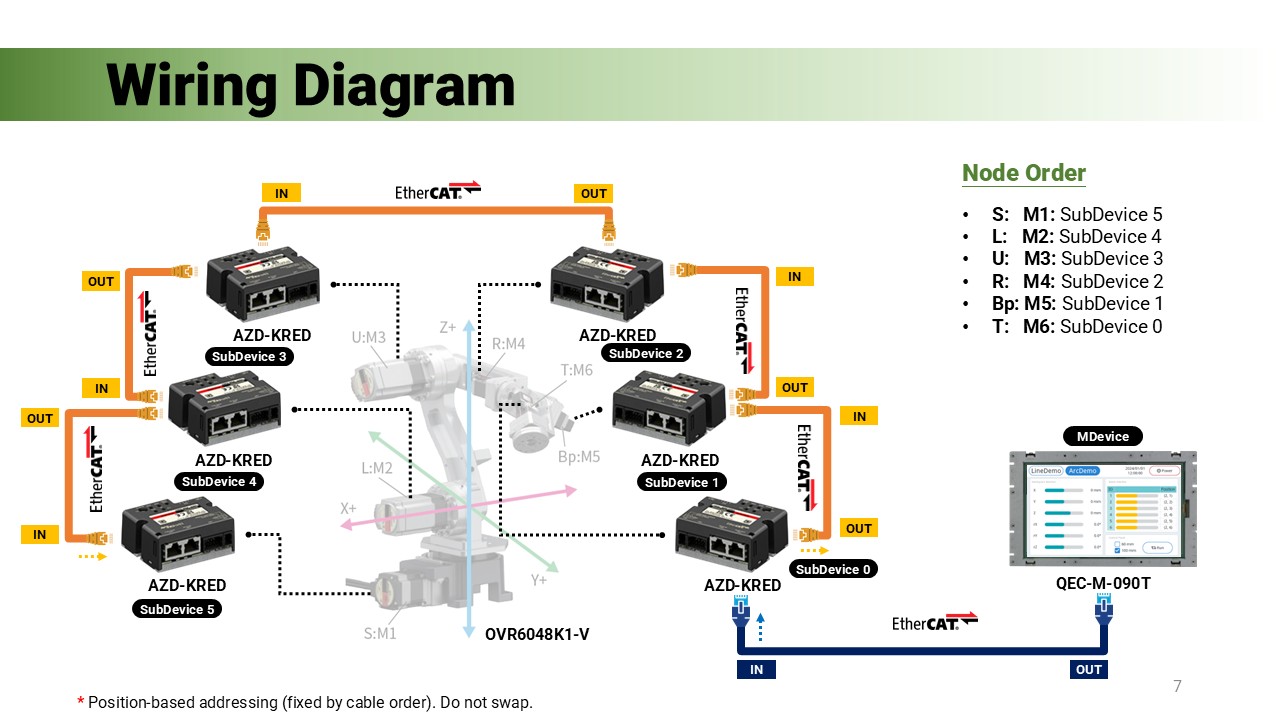

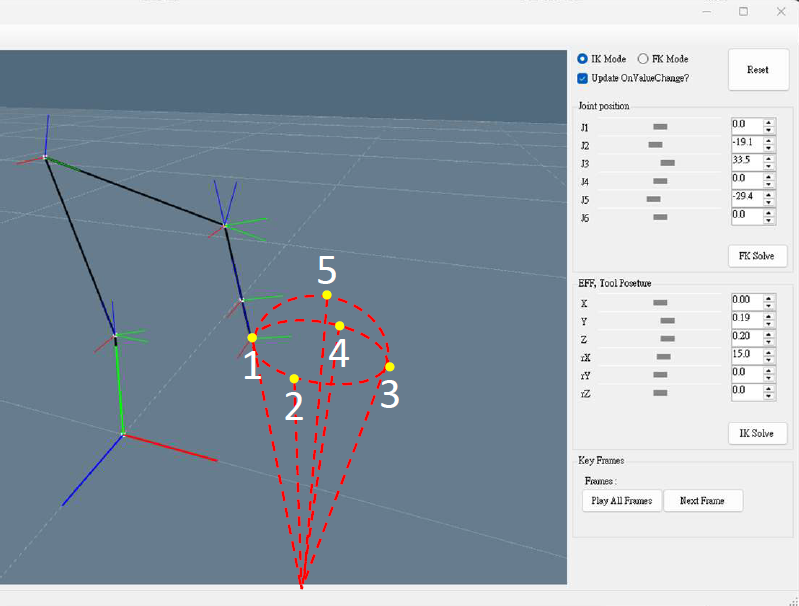

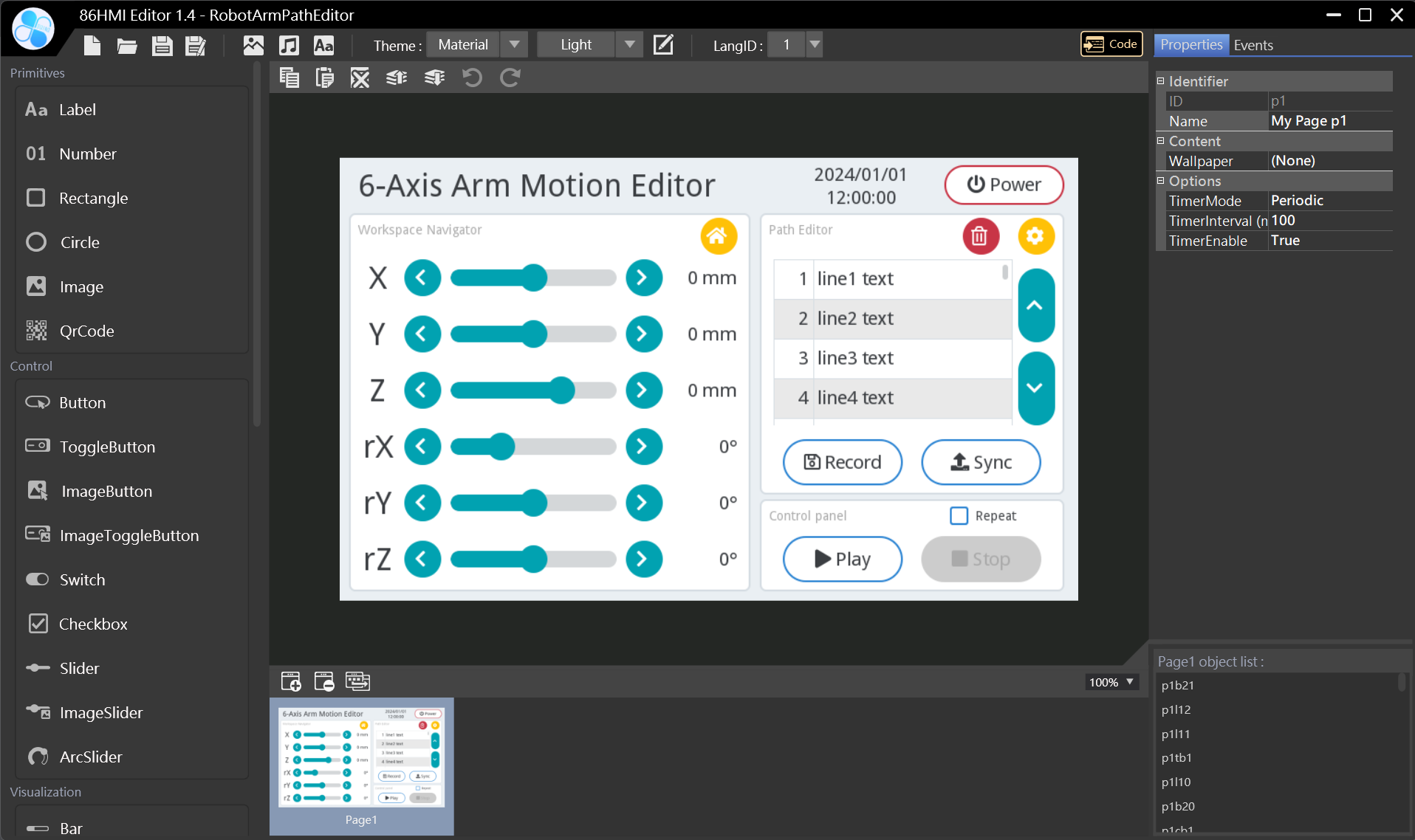

The validated system adopts the QEC-M-090T as an integrated EtherCAT MDevice and HMI platform. Through real-time EtherCAT communication, the controller connects to the OVR 6-axis robot arm drives, forming a single-node Motion + HMI architecture.

Key system components include:

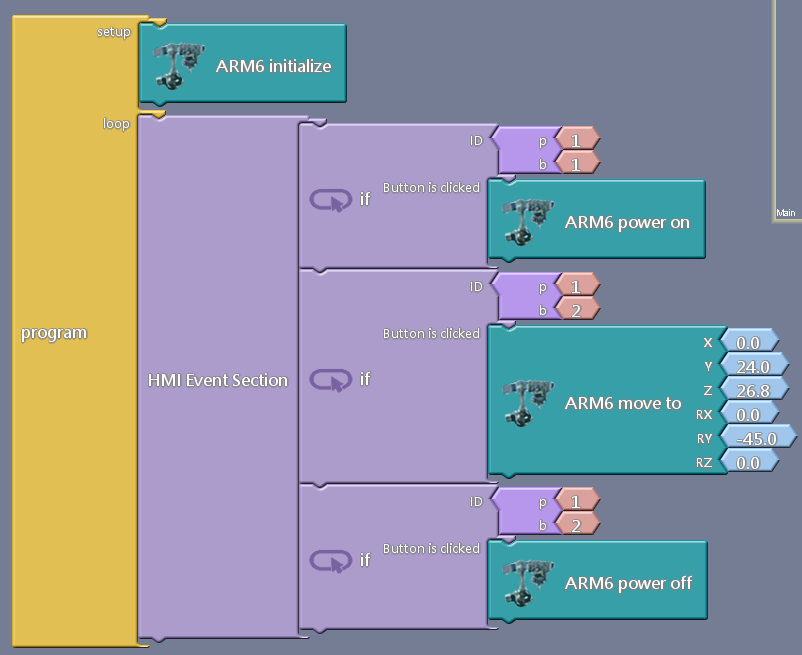

At the software level, ICOP uses the 86Duino IDE (open-source, C/C++ architecture) as the primary development environment, establishing a reusable robot arm control workflow:

This workflow can be used as a standard development reference when deploying robot arm applications on equipment, reducing initial integration risks.

Through this integration validation, ICOP demonstrates several practical advantages of the QEC EtherCAT MDevice platform in 6-axis robot arm applications:

This architecture is particularly suitable for machine builders and system integrators who have adopted - or are evaluating - the Oriental Motor OVR 6-axis robot arm and wish to retain full control over the motion and application layers.

ICOP will continue to build on the QEC EtherCAT platform to deepen technical integration with robot arms and motor solutions provided by Oriental Motor, and to offer:

Through closer technical collaboration, ICOP aims to help customers shorten development cycles and expand the deployment of robot arm applications in industrial equipment.

Oriental Motor provides a wide range of industrial motion products, including stepper motors, servo systems, drivers, and robotic solutions for diverse automation applications.

More information: Oriental Motor Website

If you are planning to deploy — or have already deployed — the Oriental Motor OVR 6-axis robot arm and would like to further explore EtherCAT-based control architectures and development workflows, please contact ICOP for technical discussions and project consultation.

For more information and sample request, please write to info@icop.com.tw, call your nearest ICOP Branch, or contact our Worldwide Official Distributor.