The static electricity generated in life can be a devastating disaster to an integrated circuit with a voltage resistance of several tens of volts.

The damage caused by static discharge to electronic products is directly observable, such as screen defects, melting or evaporation of metal circuits, changes in component resistance, destruction or breakdown of the oxide layer, and even the impact on the microprocessor causing the controller to mistake.

Electrostatic discharge (ESD) immunity testing is a critical electromagnetic compatibility (EMC) test, and IEC61000-4-2 is one of the standards used to test the ESD immunity of electronic equipment.

The object of this test is to establish a common and reproducible basis for evaluating the performance of electrical and electronic equipment when subjected to electrostatic discharges. In addition, it includes electrostatic discharges which may occur from personnel to objects near vital equipment.

| Level | 1 | 2 | 3 | 4 | X |

|---|---|---|---|---|---|

| CD | 2KV | 4KV | 6KV | 8KV | Special |

| AD | 2KV | 4KV | 8KV | 15KV | Special |

∗ X is an open level.

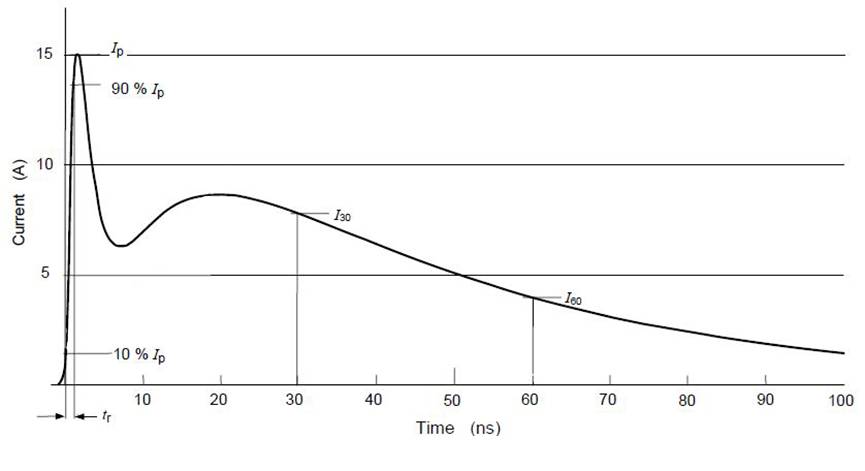

| Level | Voltage (KV) | First peak current (±10%) Ip | Rise time Tr | Current at 30 (±10%) I1 | Current at 60 (±10%) I2 |

|---|---|---|---|---|---|

| 1 | 2 | 7.5A | 0.7~1ns | 4 | 2 |

| 2 | 4 | 15A | 0.7~1ns | 8 | 4 |

| 3 | 6 | 22.5A | 0.7~1ns | 12 | 6 |

| 4 | 8 | 30A | 0.7~1ns | 16 | 8 |

∗ Note: This table is simplified for the purpose of giving a quick overview. For detail as the official IEC 61000-4-2.

| Charge capacitance | 150pF (typical) |

| Discharge resistance | 330Ω (typical) |

| Charge resistance | 50MΩ~100MΩ |

| Output voltage Contact discharge/ Air discharge | 8KV / 15KV |

| Output voltage display accuracy | ±5% |

| Output voltage polarity | Positive and negative (switchable) |

| Holding time | 5 seconds (less) |

| Discharge operation mode | Single shot (discharge interval 1 second or more) |

| Waveform of discharge current | Refer to the below figure |

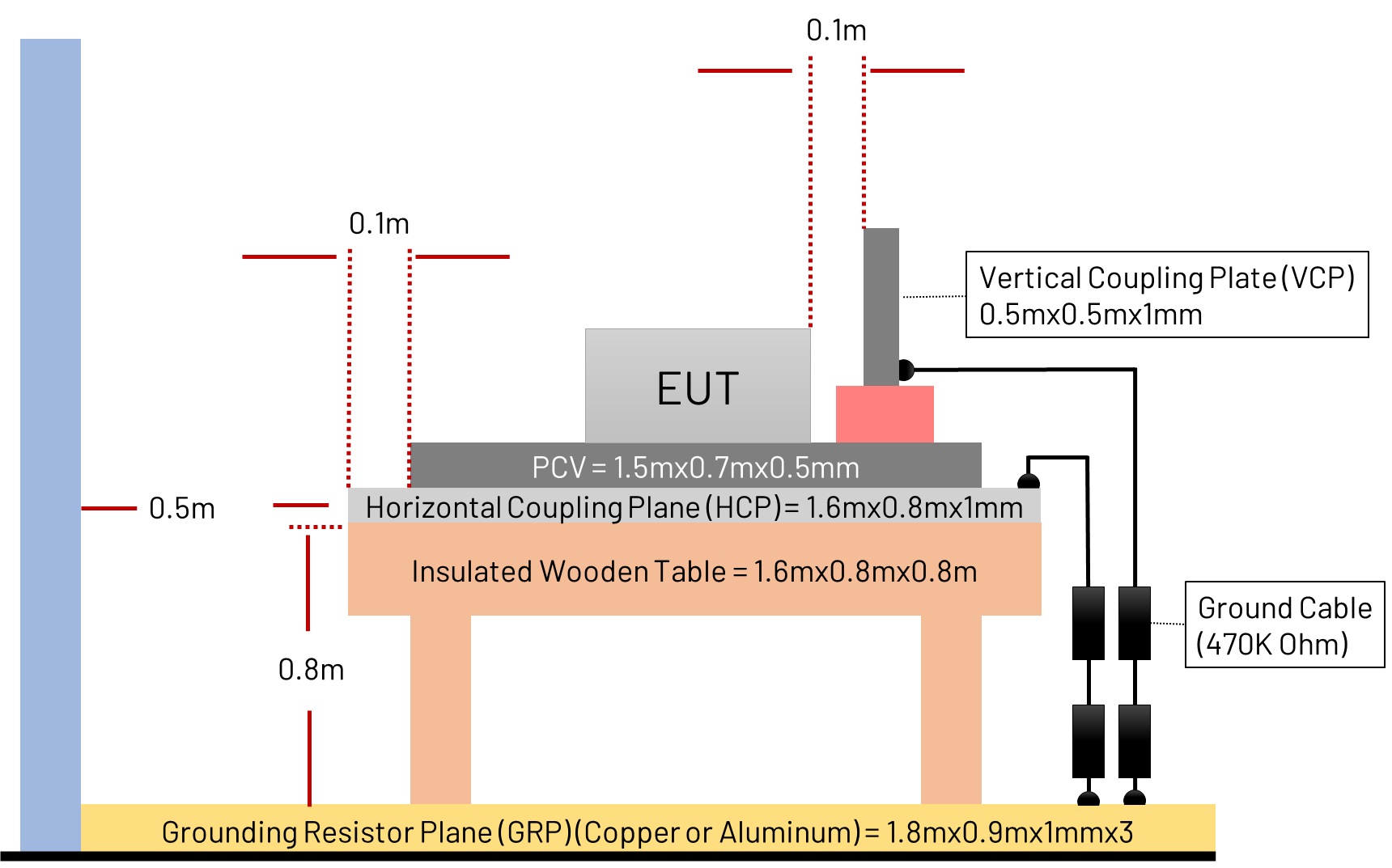

Test set-up for table-top equipment, laboratory tests: A wooden table of 0.8m height shall be set on the ground plane. 1.6m x 0.8 m horizontal and 0.5m x 0.5 m vertical coupling planes shall be put on the table. Insulating support of 0.5 mm thickness shall be inserted between the EUT/cables and the horizontal coupling plane.

The electrostatic discharge test consists of direct discharge and indirect discharge.

The test results are classified according to the specifications and operating conditions of the EUT as follows.

The product is considered to have a good monitoring result if it meets the functional requirements specified in the product specification. The test report must contain test conditions and test results.

For more info and sample request, please write to info@icop.com.tw, call your nearest ICOP Branch, or contact our Worldwide Official Distributor.