Severity: Notice

Message: Undefined index: HTTP_ACCEPT_LANGUAGE

Filename: front/Model_main.php

Line Number: 35

Backtrace:

File: /var/www/html/application/models/front/Model_main.php

Line: 35

Function: _error_handler

File: /var/www/html/application/controllers/Home.php

Line: 1292

Function: init

File: /var/www/html/index.php

Line: 315

Function: require_once

An industrial PC is a computer intended for industrial purposes (production and services), with a form factor between a nettop and a server rack. Industrial PCs are designed for industrial environments that need higher dependability and precision standards; Industrial PCs offer different ways than consumer PCs in terms of reliability, compatibility, expansion options, and long-term supply.

Industrial computers usually have the following characteristics:

With the IoT era, the interconnections between devices have grown substantially. They might install in remote or harsh environments, the failure from them has had a direct and significant impact on the company. There are so many risks that show the user's solution requires not only need software support but also rugged hardware, which means reliable hardware become more and more critical.

Fanless Design can not only low down your noise, power consumption, and lightweight but also protect your computers. Most Industrial PCs are cooled without a fan to protect the electronics and ensure optimal reliability, particularly in harsh environments subject to dust, debris, or other airborne particulates.

Industrial PCs must build with higher reliability and a long operating time, which requires a good hardware design and rugged components. These components need resistance to harsh environments and can operate 24/7, and this is where a consumer desktop PC most appears a failure.

Industrial PCs can perform many different tasks, including factory automation, remote data collection, and surveillance. ICOP’s systems are highly configurable to suit your individual project needs. In addition to reliable hardware, we can provide OEM services such as custom branding, imaging, and BIOS customization.

Industrial computers are engineered to withstand harsh environments, designed for stable work, even if there are high shock/vibration, wider working temperature, and dust in the operating environment.

Customize systems to suit the application's specification need also are industrial PCs' advantages. For example, To effectively communicate with devices such as PLCs, sensors, and legacy equipment, industrial PCs come with extensive I/O options and additional functionality.

The Product Lifecycle and its related longevity are key factors in controlling the product quality and market development cost for electronic equipment suppliers. Implement a solid composition of the product roadmap, version control, End-of-Life (EOL), last buy announcements, the product upgrade path for stability, and the continuation of electronic equipment suppliers’ product design.

Industrial PC is designed according to the terminal application. For working environments where consumer PCs cannot be used, industrial computers are a must. Wherever the requirements of powerful computing appear, industrial computers will appear, and they will bring great value to your organization.

ICOP works closely with the chip manufacturers such as Intel, NXP, and DMP, using the most current chip architecture to ensure our customers' best architecture and technology advances.

Suppose you are looking for a long lifecycle solution with rich I/O options, including ODM or OEM. Or have questions about solutions' damage from environmental factors, please feel free to contact ICOP Technology.

ICOP Technology is the world’s leading manufacturer of industrial embedded computers, industrial embedded controllers, industrial motion controllers, and industrial panel PCs used in the automation of numerous control systems.

ICOP industrial devices helps companies improve product quality, product reliability, lower manufacturing costs, and exceed consumer expectations for high quality products at an affordable price.

Due to the increasing efficiency and reliability of automation computing products, many CNC machine applications have become much more cost-efficient. They are looking for an upgrade solution for their system with a powerful controller to increase their performance, productivity, and reliability.

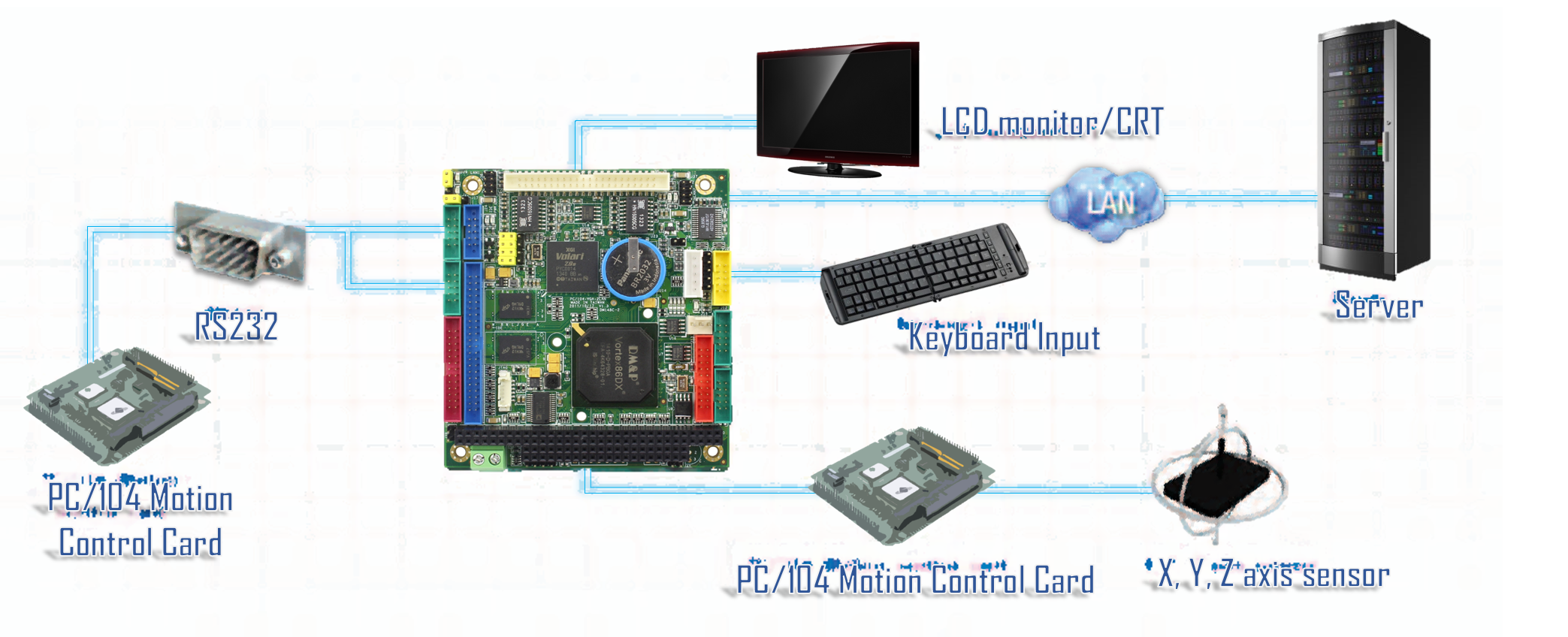

The customer is looking for an industrial single board computer for their CNC machine that could process the CAD/CAM numerical control information and show relevant system information on the LCD monitor. This CPU module needs to be able to communicate with the legacy controller, and also needs high speed Ethernet to connect to a server and to download CAD/CAM files. The requirements are based on their needs are following:

The VDX-6358RD is the best choice to be installed inside the CNC machine. It runs the CAD/CAM numerical control program on Linux, and can communicate with the legacy controller through serial communications. The VDX-6358RD also links to the servers through Ethernet with TCP/IP protocol.

VDX-6358RD is a PC/104 800MHz CPU module which supports LCD and CRT output, Ethernet and RS232/422/485 communication. This module also supports a wide temperature range with shock and vibration tolerance. VDX-6358RD provides high performance computing power to handle multiple tasks such as the graphic based interface, CAD/CAM program, and device control at the same time.

Please write to info@icop.com.tw, call your nearest ICOP Branch, or contact our Worldwide Official Distributor for more info and sample request.