Severity: Notice

Message: Undefined index: HTTP_ACCEPT_LANGUAGE

Filename: front/Model_main.php

Line Number: 35

Backtrace:

File: /var/www/html/application/models/front/Model_main.php

Line: 35

Function: _error_handler

File: /var/www/html/application/controllers/Home.php

Line: 1292

Function: init

File: /var/www/html/index.php

Line: 315

Function: require_once

The QEC-RXXMP series is an EtherCAT stepper motor controller capable of high-speed synchronization at 125μs while simultaneously driving three axes of two-phase bipolar 0.9-degree stepper motors. Equipped with A, B, and Z encoder interfaces, it achieves closed-loop control of the motors.

Its core functionalities support the EtherCAT standard CiA402 communication and G-code programming language, significantly enhancing the ease of integrating the controller into various systems, especially for CNC applications. The compatibility with G-code demonstrates the controller's high adaptability to this programming language.

The QEC-RXXMP series has passed the verification of conformance testing tools and is suitable for various traditional industrial automation applications, such as management and precise motion control. By utilizing the EtherCAT protocol, it enhances the stability and reliability of the system. This makes it ideal for equipment requiring fine control, such as automated production lines or robots.

The QEC-RXXMP series is a standard EtherCAT SubDevice that requires an EtherCAT MDevice to operate the device. It supports three operating modes: Free Run, SyncManager2, and Distributed Clock (DC). Utilizing the efficient EtherCAT protocol, the QEC-RXXMP series controllers can complete data exchange within an ultra-short cycle time of 125 microseconds, thereby achieving high-precision synchronous motion control of three-axis stepper motors. Whether it's a machine vision system that requires rapid response or a robotic arm that demands precise positioning, this controller can deliver ultimate control performance.

The QEC-RXXMP series not only supports the CiA402 drive profile, a standard within EtherCAT, allowing seamless integration with a variety of control systems; But it also deciphers G-code, a widely used programming language in CNC machine tools. This capability makes it adept in complex CNC machining and precise motion control domains.

The supported modes in CiA402 include PP (Profile Position), Homing, CSP (Cyclic Synchronous Position), and CSV (Cyclic Synchronous Velocity). For instance, in PP mode, the controller drives the motor to a target position; in CSV mode, it accelerates the motor to a target speed, with all motion parameters being adjustable in real-time.

As for G-code, being a prevalent CNC programming language, it provides a set of instructions for CNC machine tools and related equipment. It specifies tool movement trajectories, speeds, rotations, and other functions like switching and coolant control. The G-code support in the QEC-RXXMP series means it can directly interpret G-code instructions, achieving fine-tuned motion control and machining operations. This allows users to program and execute complex machining tasks using standard G-code files without the need for cumbersome conversions or additional programming, thereby enhancing efficiency and reducing the likelihood of errors.

The support for CiA402 ensures that the controller is capable of handling complex motion control tasks, such as position, speed, and torque control. Meanwhile, its compatibility with G-code opens up direct support for CNC programming. This makes the QEC-RXXMP series not just a stepper motor controller, but a comprehensive motion control solution.

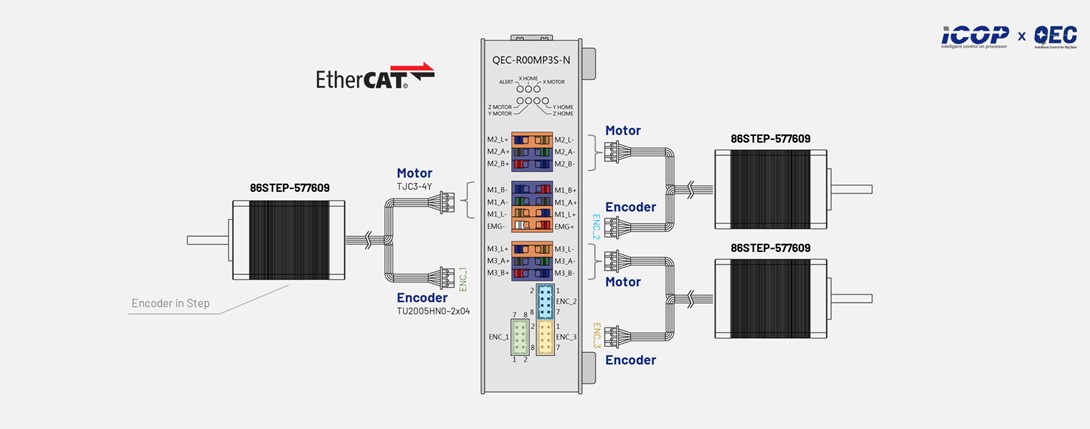

The QEC-RXXMP series can control up to three axes of stepper motors, supporting two-phase bipolar stepper motors with a 0.9-degree step angle. These motors can be directly connected to the QEC-RXXMP device. This device is compatible with encoders for closed-loop control of the stepper motors.

This EtherCAT stepper motor controller is capable of achieving 125μs high-speed synchronous control across three axes, effectively managing complex motion requirements. It can continuously provide a maximum drive current of up to 4.84A (using the TB6600HG), ensuring precise control even for the most demanding motors. The motor current output can be adjusted via DIP switches located at the bottom of the device, allowing fine-tuning of performance based on the specific application. Additionally, when the motor is not in motion, the QEC-RXXMP series automatically reduces the current, thereby lowering energy consumption and wear, which in turn extends the motor's lifespan. This device allows all three motor axes to share a single power source, reducing the complexity of wiring.

(For information about the 86STEP-577609 stepper motor, please refer to: 86STEP | 86Duino)

The QEC-RXXMP series can achieve closed-loop control of motors through its A, B, and Z encoder interfaces with differential signals, ensuring precise control, as well as strong anti-interference capabilities and reliable feedback. It also supports a high resolution of up to 16 micro-steps, which is crucial for maintaining the accuracy of motor position and speed, especially in tasks that require high precision. Each motor is equipped with a set of digital input channels that can be used for homing.

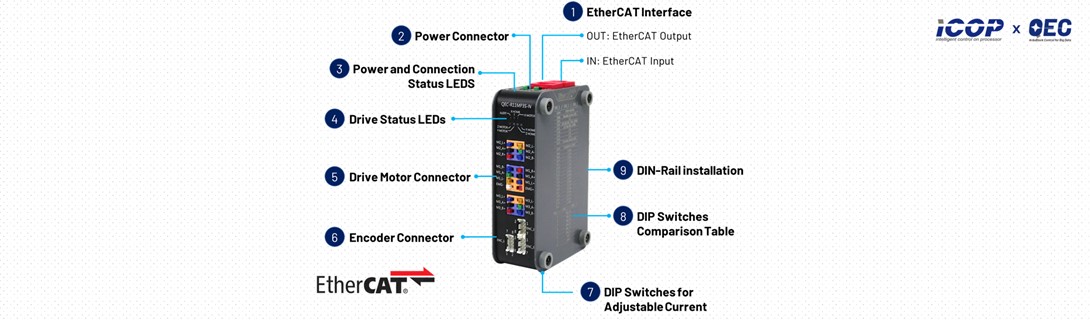

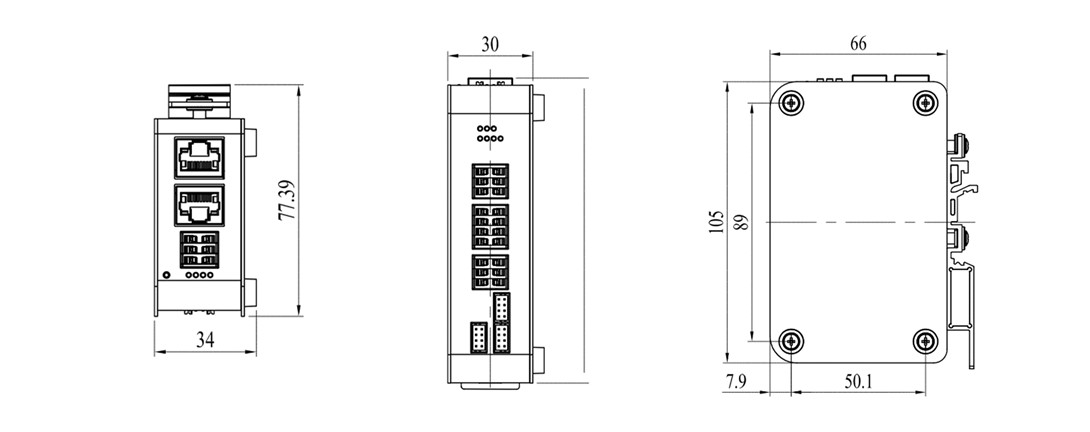

The QEC-RXXMP series has a compact size of 107.45 x 77.39 x 34 mm, making it very convenient for system installation via Din-Rail mounting. It operates within a temperature range of -20°C to +70°C and is equipped with two network ports for EtherCAT network redundancy, enhancing system reliability and stability.

Additionally, the QEC series products feature internal monitoring capabilities, able to track the internal status of voltage, current, and working temperature. These data can be used to calculate the product's carbon emissions, aiding in carbon footprint tracking for the product.

All these monitoring data can be accessed via API calls or viewed through the graphical tools built into the QEC MDevice station software. This makes them a valuable source for big data collection, providing additional value to industrial manufacturing products.

The QEC-RXXMP series EtherCAT stepper motor controllers, with integrated CiA402 and G-code support, offer powerful hardware functionality and a highly adaptable control solution. They are capable of precisely executing motion control sequences ranging from simple to highly complex, making them suitable for a wide range of industrial applications.

For more info and sample request, please write to info@icop.com.tw or info@qec.tw, call your nearest ICOP Branch, or contact our Worldwide Official Distributor.