Severity: Notice

Message: Undefined index: HTTP_ACCEPT_LANGUAGE

Filename: front/Model_main.php

Line Number: 35

Backtrace:

File: /var/www/html/application/models/front/Model_main.php

Line: 35

Function: _error_handler

File: /var/www/html/application/controllers/Home.php

Line: 1292

Function: init

File: /var/www/html/index.php

Line: 315

Function: require_once

ICOP’s QEC-M-01 is an EtherCAT MDevice system based on Vortex86EX2 processor. The development environment uses industrial-Arduino software, 86Duino IDE, supporting EtherCAT API, which performs real-time field monitoring and big data collection and supports graphical programming tools, making it easy to hire software engineers and shorten the market time.

People can also work with AI software to calculate the carbon footprint of power consumption and temp to enhance the field-system process.

QEC-M-01 has a built-in high endurance 2GB SLC eMMC, designed to provide a stable and reliable operating system. Users can upload the developed executable files and required images or data, such as HMI images, to the QEC-M-01's SLC via the 86Duino IDE without affecting the performance of the MDevice system.

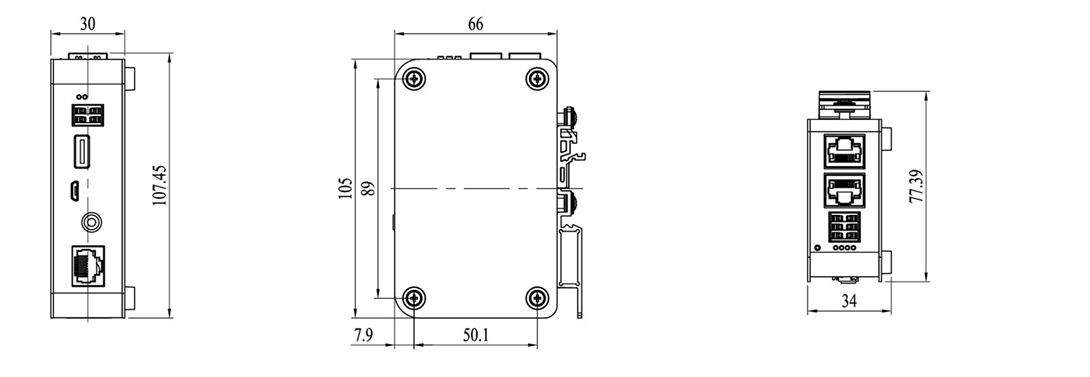

QEC-M-01's dimension is 107.45 x 77.39 x 34 mm, could be mounted via Din-Rail. Operating temperature is from -20°C to +70°C; it can be placed directly in the field outdoors and ensures that the machine can work in harsh environments.

QEC-M-01 has two networks for EtherCAT Cable Redundancy, one Giga LAN for external network connection, RS485 signal pins, HD Audio, and USB; All provide an off-the-shelf API to use. Users can quickly collect data over EtherCAT and transfer data to a server via Giga LAN, and then big data can easily to construct by MySQL Library.

In addition, users can connect their existing systems via RS485 signals, such as PLC or CNC.

QEC-M-01 is an EtherCAT MDevice with real-time, reliable, and synchronous control. And the industrial Arduino makes it an easy-to-develop, stable, and economical automation system, allowing users to develop EtherCAT quickly.

The QEC MDevice is highly compatible with third-party EtherCAT devices for communication, such as servo, I/O, etc. For taking full advance of EtherCAT, It supports CoE, FoE, DC, and EtherCAT cable redundancy to use other EtherCAT SubDevice flexibly.

The QEC MDevice has precise synchronization (min.125μs), and its 86Duino IDE provides less than 1us jitter time in the minimum cycle time; it could apply to highly synchronized and precision automatic applications, like motion control and I/O control. (Read More: EtherCAT MDevice’s Benchmark - QEC)

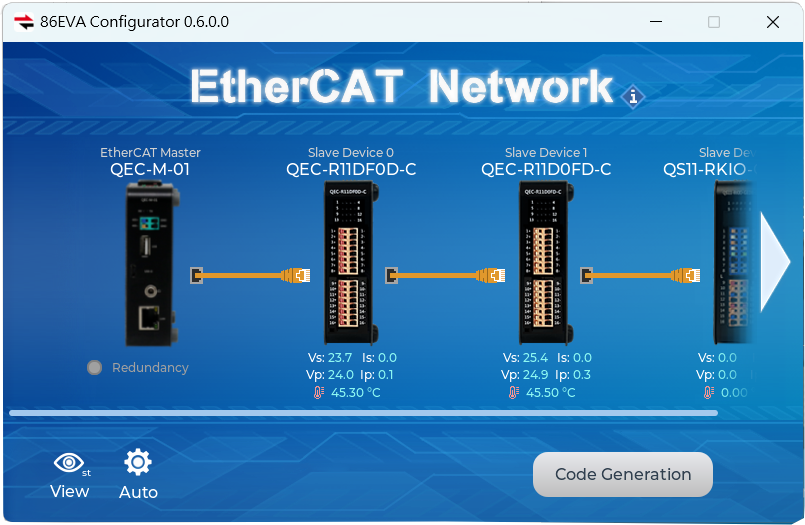

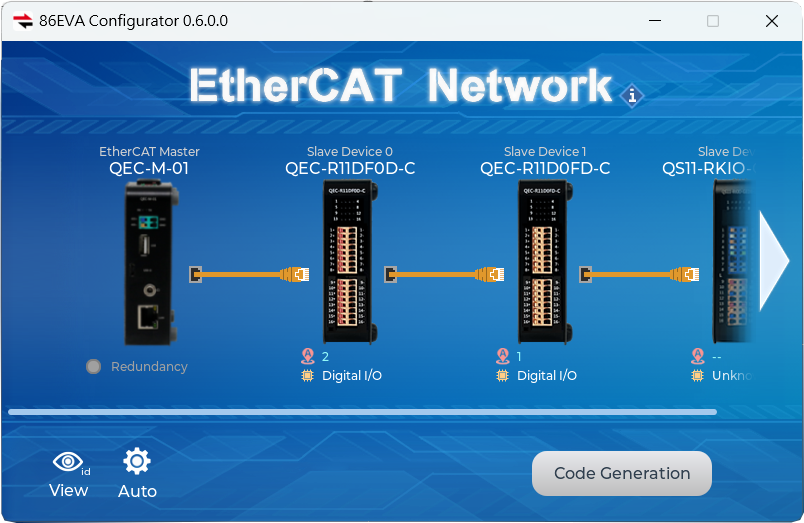

All QEC series can monitor hardware's voltage, current, and temperature, providing carbon emission calculations for industrial manufacturing and further assisting in carbon footprint tracking. All information can be used for big data, and users can be presented through API calls, or viewed through the graphical tool.

Figure: 86EVA's QEC Device Monitoring

Most industrial applications require high precision and synchronous operation speed, which is highly complex and has a long development cycle.

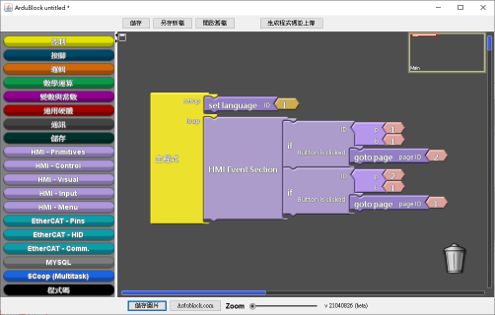

However, using the QEC-supported 86Duino IDE (Industrial-Arduino), users can develop with the following graphical tools:

Users can use these graphical tools to develop their EtherCAT systems. First, use 86EVA to config the EtherCAT MDevice and SubDevice quickly; then, open 86HMI to design the user interface to improve the system's operability; finally, use ArduBlock to construct the control actions by building blocks.

For more info and sample request, please write to info@icop.com.tw, call your nearest ICOP Branch, or contact our Worldwide Official Distributor.